Facilities

Pattern Making Department.

Students learn practically the art of pattern making for vaious components, which ultimately will produce various products like readymade garments, knitwear, shoes, upholstrey, parachute and other heavy duty industrial products.

They will understand the importance of making accurate patterns which ultimately will develop in to a product with perfect shape and accurate measurements.

This will enhance the style of the product while retaining user comfort.

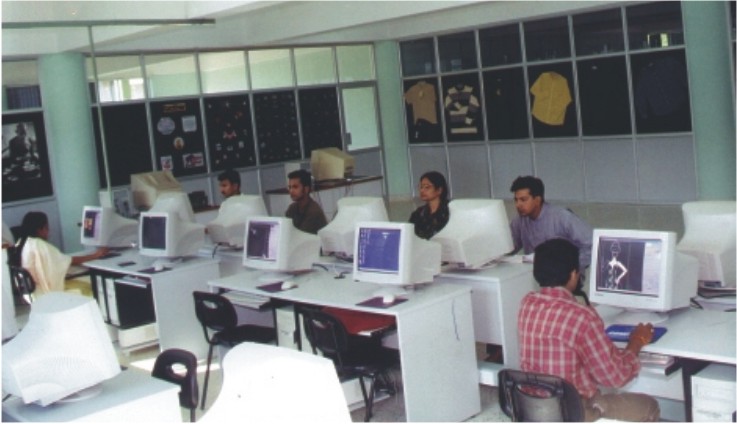

Computer Aided Design (CAD) Lab.

This is the most important department and translates the pattern making department in to an area of accuracy and efficiency. Students who have completed their course in the pattern making department will graduate to the cad lab.

There are many disciplines of learning in the cad lab like

Design of fabrics and other raw materials.

Pattern making, grading for various sizes and finally efficient marker for saving precious raw material.

Learning about time and attendance, inventory control and production control.

Finally design, manufacturing and control from one source making it a complete design studio.

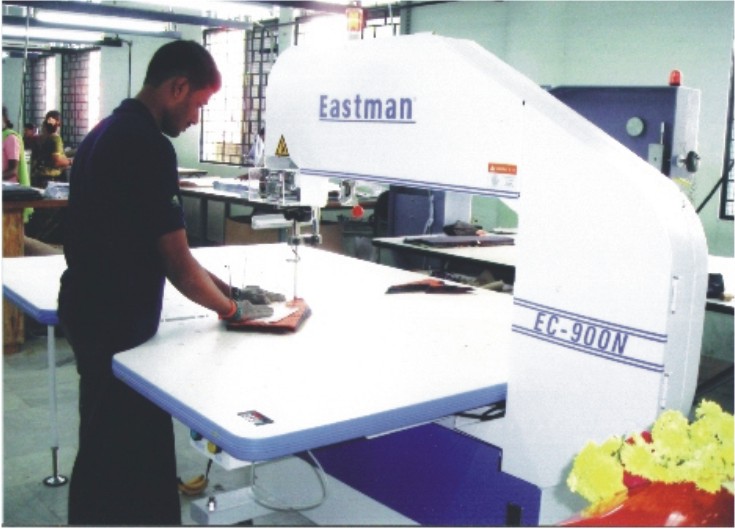

Cutting Department.

After making accurate patterns, students will be trained in the art of cutting.

The first stage is to cut the component from the layer by a straight knife or round knife machine.

The final stage is to finish the cutting for perfect shape and accuracy on band knife cutting machine.

The objective of the cutting department is to deliver components of perfect shape and to an accuracy of 1mm to the showing lines.

This will ensure perfect quality products.

Sewing Department.

After recieving accrate components from the cutting department and passing the quality control checks , students are exposed to the sewing department as follows

Manufacture of accurate components.

High speed assembly to bring down costs and make the product most competetive.

Finishing Department.

Irrespective of the products manufactured by the sewing department, the finishing department will clean the product by using spot cleaning chemicals, which where acquired during the process of production.

There after the products will be steam finished and packed size ratio wise and ready for dispatch.

Engineering Department.

Understanding the engineering of each machine is very vital to good quality and efficient production.

Preventive maintenance is the key to zero down time and avoiding production losses to the plant.

Students acquire valuable knowledge in the engineering department.

The Design Studio.

This is the temple of learning to design, manufacture and presentation with quality and price.

It offers a perfect interaction between the college and the industry and gives an oppurtunity to students to explore their creativity while understanding the market demand.

It brings every students to the market place so that they get exposed to the realities of the market.

Well Come!